In the ever-evolving landscape of materials science, the quest for advanced materials that offer exceptional properties and applications continues unabated. One such material that has caught the attention of industries ranging from electronics to packaging is Polyimide (PI) Metallized Film. Combining the remarkable characteristics of polyimide with the advantages of metallization, this innovation is reshaping industries and opening up new possibilities for various applications. In this blog, we’ll delve into the world of PI Metallized Film, exploring its properties, applications, benefits, and the potential it holds for the future.

Understanding PI Metallized Film

Polyimide at the Core

Polyimide, known for its exceptional heat resistance, mechanical strength, and electrical insulation properties, forms the base of PI Metallized Film. This versatile polymer has long been favored in industries like aerospace, electronics, and automotive for its ability to perform under extreme conditions.

The Metallization Advantage

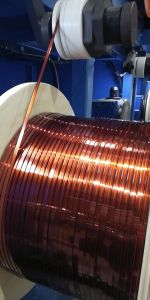

Metallization involves depositing a thin layer of metal, often aluminum or copper, onto a substrate. When applied to polyimide film, it brings an array of new attributes to the material, making it suitable for applications beyond its traditional roles. The metallized layer not only adds a glossy, reflective surface but also endows the film with enhanced electrical conductivity and electromagnetic shielding capabilities.

Applications of PI Metallized Film

Electronics and Circuitry

The electronics industry has been quick to recognize the potential of PI Metallized Film. Its excellent combination of electrical insulation and metal-like conductivity makes it an ideal candidate for flexible circuits, printed circuit boards (PCBs), and even flexible displays. The film’s ability to withstand high temperatures also makes it an attractive choice for applications in which other materials might falter.

Advanced Packaging

In the world of packaging, PI Metallized Film has sparked a revolution. Its heat-resistant nature and moisture barrier properties make it an excellent choice for food packaging, particularly for items that require prolonged shelf life. Moreover, its glossy and reflective surface provides an attractive visual appeal, adding to the overall presentation of the packaged product.

Space and Aerospace

Given its resistance to extreme temperatures and vacuum conditions, PI Metallized Film has found its way into space and aerospace applications. It serves as a reliable material for insulation blankets on spacecraft, protecting sensitive components from the harsh environment of space.

Benefits of PI Metallized Film

Thermal Stability

One of the standout features of PI Metallized Film is its exceptional thermal stability. It can withstand temperatures well above those tolerated by conventional plastics, making it suitable for high-temperature environments.

Electromagnetic Shielding

The metallized layer on PI Film contributes to its electromagnetic shielding capabilities. This is crucial in applications where electromagnetic interference needs to be minimized, such as in electronic devices and circuits.

Versatility

PI Metallized Film’s versatility is evident in its myriad applications across industries. From electronics to aerospace to packaging, it adapts to diverse needs and continues to push boundaries.

Future Prospects

As technology advances and industries continue to evolve, the future prospects for PI Metallized Film are promising. Its unique blend of properties makes it a prime candidate for innovations in fields such as flexible electronics, energy storage, and even medical devices. Researchers and engineers are actively exploring ways to enhance its properties further, potentially unlocking new dimensions of its potential.

Leave a Reply